Managing Joinery Quality

Recent reporting in the New Zealand Herald has highlighted concerns in the construction industry around non-compliant door and window joinery products. The article outlines issues such as inaccurate or misleading compliance documentation and the increased risk this poses to building weathertightness across the country. While this reinforces the challenges we have seen in the industry, it also emphasises the importance of the processes we already follow to manage joinery quality and performance on our projects.

At Agents of Architecture, our role includes carefully managing the design and construction factors that contribute to long-term building performance, particularly the risks associated with the building envelope. Joinery forms a critical component of that envelope, with numerous high-risk junctions and interface complexities that require thorough technical attention. In New Zealand’s climate, where weathertightness failures have had significant and ongoing impact, architects and façade engineers must apply rigorous review, coordination, and substantiation to reduce the risk of future issues. This forms an essential part of how we design buildings that meet both performance expectations and compliance requirements.

How We Manage Joinery Quality Throughout the Project

1. Product Compliance Review

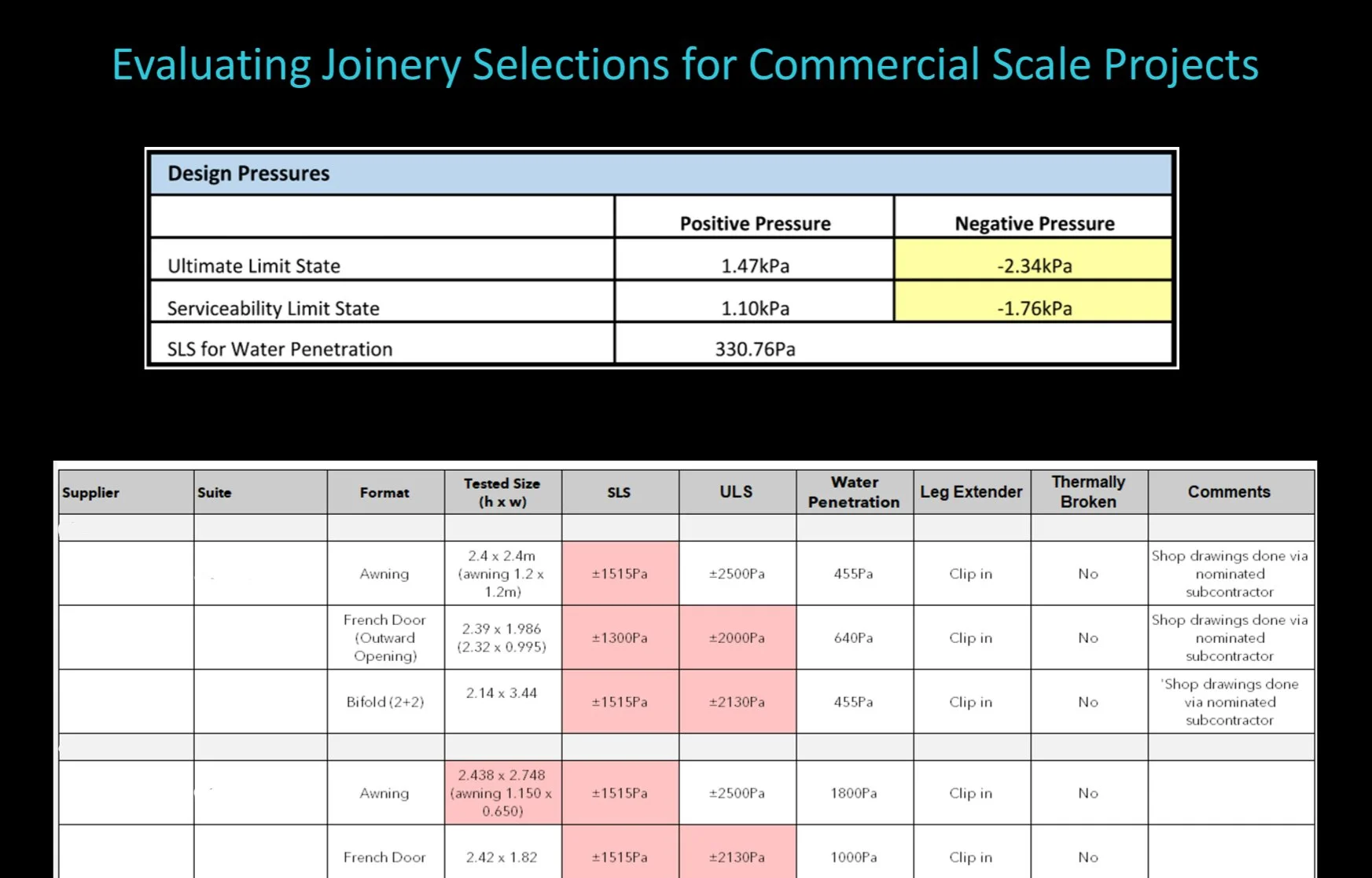

At the outset of the project, we complete a focused comparison and review of the proposed joinery systems to determine their suitability for the building envelope design. This establishes the technical basis for selecting systems that can meet the project’s performance, integration, and compliance requirements.

Our review considers:

Supplier product literature, testing evidence, and performance statements

How the system responds to project-specific conditions such as wind loads, exposure, and seismic movement

Any limitations, dependencies, or project-specific risks associated with the product

This early review confirms product capability and establishes a strong foundation for coordinated design and documentation, reducing the risk of issues emerging once the system moves into detailed development or consent stages.

2. Façade Engineer Involvement

When the project complexity and compliance pathway requires specialist input, we engage façade engineers to support the design and verification of the building envelope.

The facade engineer may support us by providing an independent review of the proposed joinery and façade systems, developing the compliance pathway for the envelope, and, on some projects, a second façade engineer may be engaged to provide a peer review.

Alongside our own review, the façade engineer assesses the joinery performance data, compliance documentation, and system suitability. Their specialist input strengthens the technical foundation of the project and supports informed decision-making.

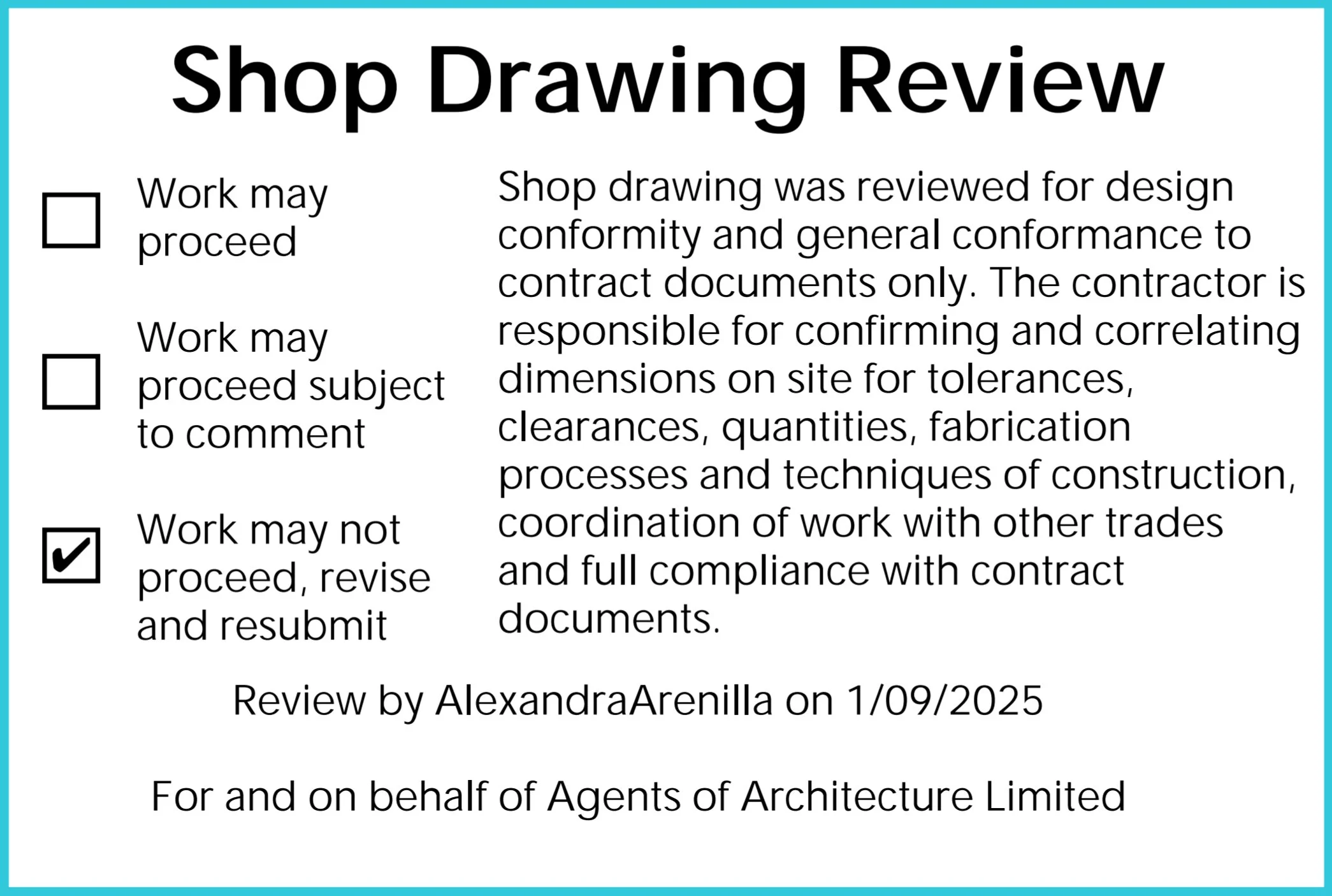

3. Shop Drawing Review

For some projects, the compliance pathway requires joinery shop drawings to be prepared before the building consent is lodged. We coordinate with the joinery manufacturer to obtain these preliminary drawings, which are reviewed in collaboration with the façade engineer to confirm their suitability for consent.

Our review typically focuses on:

Junctions and interfaces with adjacent building elements

Frame profiles, opening types, and dimensions

Hardware selections and operation clearances

Drainage paths, sill and jamb configurations

Air seal locations, continuity, and integration with adjacent building envelope components

Recommendations or requirements provided by the façade engineer

Alignment with the proposed compliance pathway

These preliminary shop drawings, once reviewed, are included within the building consent submission.

Following consent, the manufacturer prepares final shop drawings for construction. We undertake a further review at this stage to confirm that the construction issue is consistent with the consented design, coordinated with the façade engineer’s input, and appropriate for fabrication and installation.

4. Construction Observation

During construction, we review the joinery as part of our site observations, focusing on installation quality and the overall performance of the building envelope. While design and shop drawings define the intended outcome, on-site observation allows us to confirm that the joinery installation, workmanship, and assembly are consistent with the approved shop drawings, interface properly with surrounding materials, and satisfy performance and compliance requirements. This helps identify and address potential issues early, supporting long-term durability and functionality.

5. On-Site Performance Testing

We also require on-site water-penetration testing of installed joinery, particularly where the compliance pathway or project complexity warrants it. This process, often referred to as the AAMA 501.2 or 502.12 tests, checks for water penetration through the window or door unit and its surrounding interface with the building’s cladding.

Testing is performed on-site by accredited professionals, following guidelines from organisations such as the Window & Glass Association NZ (WGANZ). This provides a realistic assessment of how the joinery, and its interfaces perform under actual weather conditions.

On-site performance testing provides insight into:

The effectiveness of flashings, sills, and junctions in preventing water ingress

Continuity and integrity of the air seal

Workmanship and installation quality under real conditions

Confirmation that the installed system performs in line with design and compliance expectations

By carrying out these tests, potential issues can be identified and addressed early, reducing the risk of long-term water damage, costly remedial work, or non-compliance. This step is a critical part of the overall quality assurance process for the building envelope.

For a deeper look at how on-site testing supports construction quality, our previous Quality Assurance article explores this topic in more detail.

Bringing the Process Together

A careful, structured approach to joinery review contributes significantly to long-term building performance. By combining product compliance review, specialist input, shop drawing reviews, construction observation, and on-site testing, we help reduce the risk of water ingress, performance failures, or future remediation.

Recent discussion in the industry serves as a reminder of why this level of diligence matters, and our established processes are already aligned with these expectations.

These steps form an important part of how we support reliable, durable outcomes for building owners, occupants, and the wider built environment.

Every project benefits from early advice. Reach out to our team to chat about how we can support your next steps.